Precast walls are constructed by casting concrete in a reusable wall mold or form which is then cured in a controlled environment, transported to the construction site and lifted into place. The main function of the precast walls is to speed up the construction process.

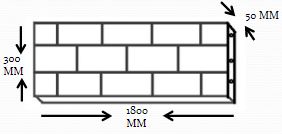

This wall can be made with the different height of 4ft, 6ft, 8ft, 10ft.The gamut of designs is provided to the customers, which is more feasible to them for making perfect decision as far as designable wall concerned.

The range of cement products we offer is manufactured using the best quality cement in accordance with industry set parameters. Before the final dispatch, these products are checked by the quality controlled on various controllers on various stringent parameters for the assurance of an optimum level of quality. Applauded for their unmatched quality, sturdy construction, fine finishing and high durability, our product are much demanded by the commercial as well as domestic establishments.

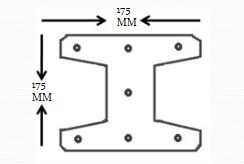

Vertical concrete posts as well as horizontal planks are casted using pre-stressed technology with designed concrete mix to achieve maximum durability and comprehensive strength. We manufacture our product on the company and install it on the side. It is vibrated by vibrating machine. Planks and beams are put in chlorinated water for required amount of time. (Minimum 07 days).

Powered by : Codeburnerz Technologies